The results are in!

Laboratories are energy intensive environments, with most teams running a wide variety of equipment. Whilst some of this can be switched off when not in use (e.g., fume cabinets and autoclaves), other equipment must stay on 24/7, such as fridges and ULT freezers.

There are some simple steps to help you get the best efficiency out of your fridges, freezers, and ULTs, such as cleaning filters regularly and replacing damaged door seals (read more about refrigeration maintenance tips here). However, an older generation, aging ULT freezer might be consuming an eye watering 30 kWh/day! And even a new model could be using as much electricity as the average UK household.[1] This is just one reason why it’s important to look beyond the initial purchase cost of a ULT freezer.

For laboratories looking to reduce their energy usage and make more sustainable choices, calculating life-time costs for equipment is more useful. Life-time costs factor in initial purchase costs as well as running costs (i.e. energy usage, HVAC impact), maintenance and repair costs (affected by warranty period) and expected life cycle.

Within our Sustainable Solutions portfolio, we feature Stirling Ultracold’s ULT freezers. Rather than traditional compressor-based refrigeration, Stirling ULTs incorporate a free-piston Stirling engine which provides efficient continuous modulated cooling. Their SU780XLE 780L unit has recently been put through its paces by independent laboratory sustainability specialist, Green Light Laboratories. Here’s what we’ve learnt…

The SU780XLE ULT freezer:

- Delivers excellent energy efficiency

- Offers high-capacity storage and space efficiency

- Demonstrates superior recovery on door opening

- It’s cold; really cold!

- Will protect your samples for longer

Read on for full details.

Benefit 1: The SU780XLE ULT freezer delivers excellent energy efficiency

An old ULT freezer could be using as much as 10-30 kWh/day, when set at -80 °C.[1] Whereas a newer unit would be expected to use between 7 and 12 kWh/day set at -80 °C, and between 5 and 10 kWh/day, when set to -70 °C.[2]

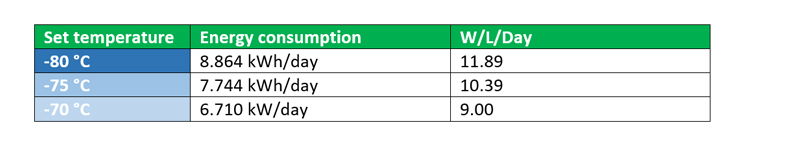

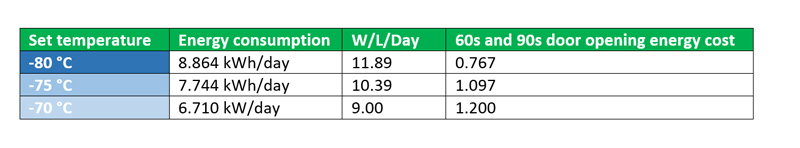

Stirling’s SU780XLE freezer can run on as little as 6.67 kWh/day at -75 °C (Weighted Average).[3] In typical laboratory conditions (ambient of 23 °C, ±1.5 °C), energy usage is around 8.86 kWh/day (setpoint -80 °C), see figure 1. However, a more useful figure to consider is a unit’s W/L/Day consumption which calculates a freezer’s energy usage according to its capacity, and allows end users to compare like for like. Here, the Stirling freezer also demonstrates excellent efficiency. See figure 1.

One tip for reducing energy usage in the lab is to increase the set temperature of the freezer from -80 °C to -70 °C. In the case of the SU780XLE, this saves the user 25%: at -70 °C energy usage is only 6.71 kW/day (or 9.00 W/L/Day).

Figure 1: SU780XLE energy consumption at three setpoints

Compared with traditional compressor-based ULT freezers, the SU780XLE generates 70–75% less heat. This reduced heat output lowers the demand on the building’s air conditioning/ventilation systems and should offer organisations further energy saving.

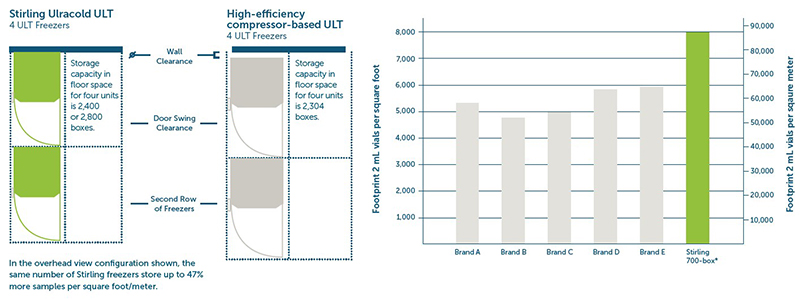

Benefit 2: The SU780XLE ULT freezer offers high-capacity storage and space efficiency

Rather than compressor-based cooling, the SU780XLE freezer incorporates a patented Stirling engine which is more space efficient and leaves more room for storing samples. Currently, the SU780XLE offers the largest m3 storage capacity per m2 of floor space available on the market. In fact, as a percentage of its footprint, the SU780XLE has a usable capacity of 47% [2], which means that laboratories can store more samples before they need to purchase additional units. With standard racking, the SU780XLE accommodates up to 600 2” boxes and with optional high-density racking, 700* 2” boxes can be stored. Such high-density sample storage means that you may be able to purchase fewer freezers while also saving valuable lab space.

But what if you need more than one freezer?

The SU780XLE can offer some benefits here as well since it has a smaller clearance for door swing than some models on the market. In addition, its upper-side air venting allows freezers to be located closer to each other. Taken together, these benefits enable organisations to maximise use of their lab space, and make the SU780XLE a great choice for creating high-density storage environments.

Benefit 3: The SU780XLE demonstrates superior recovery on door opening

Frequent and prolonged freezer door openings can lead to ice build-up and will require more electricity. To work more sustainably, whenever possible, laboratories should reduce the frequency and duration of door openings. This can be done by keeping samples organised, ideally with an inventory management system. Knowing where your samples are located allows you to plan what needs to be removed, from where within the freezer, before opening the door. Even storing frequently used samples near the front of the freezer and clearing out old samples and reagents can help.

The addition of freezer racking will increase storage capacity, as well as improve organisation and temperature stability.[4] You could also consider choosing colour-coded freezer racking, which can facilitate freezer sharing and aid emergency protocol (e.g., which samples should be saved first in an emergency).

The SU780XLE will complement these ‘good practices’ with its superior temperature recovery. During independent testing, this model demonstrated very efficient recovery to its mean temperature. Even with 9 x 60 second door openings, the freezer used less than 10 kW/day (setpoint -70 °C).[2]

The Stirling engine delivers continuous, modulated cooling which eliminates on/off cycling that compressor-based models use to regulate temperature. This results in more consistent temperatures (within ±1 °C at steady state) and enable quick return to -80 °C after door opening. Using the ENERGY STAR® Final Test Method, recovery from door opening is 35 minutes at -80 °C.

Figure 2: SU780XLE energy consumption at three setpoints

The energy consumption at the three temperature setpoints and the energy cost of carrying out two timed door openings (60 seconds and 90 seconds) at each setpoint.

Independent studies conducted by Green Light Laboratories indicate that adding freezer racking should further improve performance by reducing the amount that the temperature rises within each compartment when the door is opened.

Benefit 4: The SU780XLE is cold; really cold!

It’s an easy assumption to make that a ULT freezer, set to -80 °C, will be -80 °C on the inside. However, the interior temperature of a ULT freezer can vary from top-to-bottom, front-to-back, and from model-to-model.

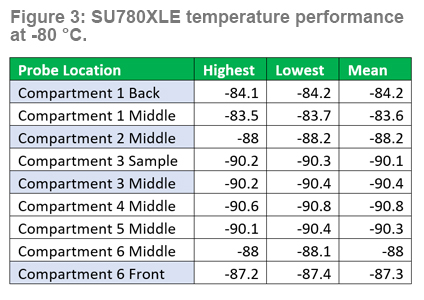

Figure 3, demonstrates that the SU780XLE delivers high temperature performance.

During independent testing, the warmest temperature was -83.5 °C at a setpoint of -80 °C. Even at setpoint -70 °C, the Stirling freezer is an ultra-cold -71.5 °C or below at all probe locations (full data available on request).

Benefit 5: The SU780XLE will protect your samples for longer

Should the worst happen, and your laboratory experiences a power failure [5], the SU780XLE will protect your samples and maintain a temperature below -50 °C for more than 5 hours. [2][6] This gives organisations valuable time to manage the situation and minimise any sample loss.

Although not tested in this particular study, it is likely that the use of freezer racking would further increase the warm-up time and give end users even longer to transfer samples to back-up units.[4] And if you’ve been paying attention, labs can use colour-coded freezer racking to help ensure that the most critical samples are rescued first.

In summary:

Thanks to the study carried out by Green Light Laboratories, we can be confident that the SU780XLE ULT freezer has earned its place in our Sustainable Solutions portfolio. It provides laboratories with high performance, excellent energy and space efficiency, and high capacity storage.

Please get in touch to discuss your requirements or if you would like to review any of the findings in more detail.

[1] The Cambridge Green Challenge: 2019

[2] STIRLING ULTRACOLD SU780XLE – Green Light Laboratories: 2022

[3] ENERGY STAR® Final Test Method

[4] ULT FREEZER RACKING STUDY – PART II Green Light Laboratories: 2019

[5] CO2 and LN2 backup systems available. We recommend an independent external monitoring system for customers storing high-value and/or critical samples.

[6] The time taken for the first probe in a freezer compartment to reach the specified threshold of -50 °C.

*To keep the vacuum release port unobstructed on the SU780XLE, it’s recommended that one box be removed. This will reduce storage capacity to 699 2-inch boxes in the high-density configuration.