Choosing the most suitable fridge or freezer for your lab’s requirements can be tricky, particularly if you want to purchase more sustainably, but without impacting your workflows or the security of your samples and reagents. Unfortunately, it’s not as simple as selecting the most energy efficient unit on the market.

Recent studies conducted by independent laboratory sustainability specialist, Green Light Laboratories highlighted several factors that could be considered when purchasing your lab fridge or freezer (in addition to energy efficiency data). These studies looked at:

- Door opening recovery

- Temperature setpoint

- Temperature performance

- Door type—glass or solid

- Freezer furniture—impact of solid drawers

In this article, we’re going to look more closely at door opening recovery. Read on to find out more about how this can influence appliance suitability and energy conservation in your lab.

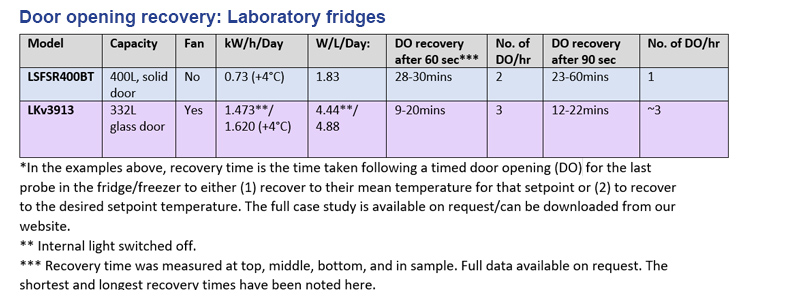

Door opening recovery: Laboratory fridges

Why is the recovery time after door opening important when choosing your fridge?

Door opening recovery time is the time taken, following a door opening, for a fridge or freezer to recover to its setpoint temperature* and it’s affected by several factors.

First and foremost, door opening recovery time is affected by the presence of a fan and how large that fan is in relation to the size of the chamber. Fans provide forced air cooling and enable the chamber temperature to recover more rapidly. However, fan circulation uses more energy than natural convection / static cooling.

Fridges without a fan usually recover more slowly than similar-sized units with a fan, but can be more energy efficient and better suited for certain requirements. For example, spark-free varieties are available for those storing flammable / volatile products. Also, a fanless model might suit laboratories that are rarely accessing their fridge (see examples below) or not storing temperature sensitive items.

How quickly the temperature recovers to its setpoint after being opened determines how often the door can be safely opened without compromising sample security. Therefore, when choosing a fridge or freezer, it’s important to consider its intended use. This is highlighted in the two examples below (all data provided by Green Light Laboratories; full case studies available on request).

Example 1:

You access your lab fridge a few times a day… once or twice in the morning and the same in the afternoon.

If you’re not storing temperature sensitive samples, then you could opt for a low energy usage unit without a fan. Since you’re not opening the door regularly, temperature recovery after a door opening may be a less important consideration than initial cost or energy efficiency.

For example, during testing, Lec Medical’s LSFSR400BT upright fridge (400 L) used 1.83 W/L/Day (without door openings). The unit has a solid door and no fan, so offers good energy efficiency. However, it’s probably better suited for those accessing their fridge once or twice an hour, and ideal for storing flammable products as it’s designed to be spark-free.

Example 2:

You frequently access your fridge. Perhaps you have multiple users accessing samples or maybe you’re sharing your appliance with another team or department.

As a result, door openings can be as frequent as 3 times each hour. In this instance, you will probably want to consider an appliance that can recover its temperature swiftly so that your samples and reagents are not negatively affected. Quick temperature recovery requires a fan.

The LKv3913 (332L) upright fridge from Liebherr used around 4.44 W/L/Day (without door openings and internal light switched off) during testing. It features a glass door and fan circulation—both of which increase energy usage. However, for busy environments, it can handle 3x 60 second door openings or 2 to 3x 90 second door openings per hour. The glass door provides good visibility of the fridge’s contents—potentially shortening door opening duration.

Full study data available on request.

Door opening recovery: Laboratory fridge freezers

Much like dedicated laboratory fridges, door opening recovery for fridge freezers is also impacted by the presence of a fan and whether the appliance has a dedicated compressor for each compartment. Units with one compressor for the fridge and a separate one for the freezer compartment are likely to recover more quickly after a door opening.

Example 1:

You access your lab fridge freezer infrequently. Perhaps once or twice in the morning and the same in the afternoon.

If you’re not storing temperature sensitive samples, then you could consider a low energy usage unit without a fan. When you are not accessing either compartment regularly, temperature recovery after a door opening will likely be less important to you than other considerations such as initial cost, warranty period, or energy efficiency.

The LSFSC298BT fridge freezer from Lec Medical used 1.110 kW/h/Day (-25 °C) (without door openings) during testing. The unit has a solid door, shared compressor and no fan, so offers good energy efficiency. Being spark-free, it’s also suitable for storing flammable products. However, this model is better suited for those accessing each compartment of their fridge freezer less than once an hour.

The shared controller means that it is not possible to control the temperature of the freezer compartment. Therefore, the option to increase the temperature to -20 °C, for example, to reduce energy usage is not available.

Example 2:

You and your team are frequently accessing both the fridge and freezer compartment of your fridge freezer. You may even share your appliance with another team or department, with someone opening the door every quarter of an hour.

In this demanding environment, you will need an appliance that can recover its temperature swiftly so that your samples and reagents are not negatively affected. Quick temperature recovery requires a fan.

Liebherr’s LCv4010 fridge freezer used 1.10 kW/h/Day (-20 °C) or 1.34 kW/h/Day (-25 °C) without door openings. The fridge compartment features a large fan making temperature recovery swift, so it can handle up to 5x 60 second door openings or 4x 90 second door openings per hour. The freezer compartment boasts its own compressor and can be opened up to 12 times for 60 seconds each hour or twice for 90 seconds (setpoint -20 °C).

The temperature of the freezer compartment can be precisely set enabling the temperature to be adjusted to conserve energy. During testing, the freezer compartment of the LCv4010 used over 100% more energy when the setpoint was -30 °C (0.805 kWh/Day) compared with -20 °C (0.4 kWh/Day).

Full study data available on request.

If you would like further information or to discuss your requirements, please contact us: enquiries@medlinescientific.com.

Part 2) looks at temperature setpoint and performance, and freezer furniture, and how these factors can influence appliance suitability and energy conservation in your lab.

[1] Lec Medical model LSFSC242 (242 L). Full case study available on request.

[2] Liebherr Mediline LCv4010 fridge freezer. Energy usage increased from 0.4 kWh/day to 0.805 kWh/day. Full case study available on request.

[3]. All units were tested at the Learning and Research Centre, University of Bristol. The laboratory space used was air conditioned with an ambient of 23 °C (+/-1.5 °C). This case study used the Logicall Wireless Monitoring system utilizing their energy monitors, temperature probes and online platform to record all the data. In each compartment a UKAS calibrated PT1000 probe was placed in the centrepoint of each shelf. In each unit tested the probe located in the centrepoint of the top compartment was always 14 cm from the top of the chamber. A sample representative probe (PT1000 probe immersed in 5 ml of glycol) was also placed in the centrepoint of the unit (figure 2).